Submersible cables are specialized electrical cables designed for deployment in underwater environments. They play a crucial role in various applications, including offshore wind farms, underwater research, oil and gas exploration, and telecommunications. These cables enable the transmission of power, data, and signals between submerged equipment and onshore facilities.

Significant for their adaptability to the challenging conditions of the deep sea, submersible cables face a multitude of hurdles. Water pressure at significant depths places immense strain on the cables, demanding robust construction to prevent damage or signal loss. Corrosion, caused by exposure to saltwater, further threatens the cables’ longevity and performance. Moreover, the hostile underwater environment, with its varying temperatures and potential mechanical disturbances, adds to the complexity of cable design.

Efforts to develop submersible cables involve utilizing durable materials, such as specialized polymers or metal alloys, that can withstand water pressure and resist corrosion. Protective layers and insulation coatings are incorporated to shield the conductors from external factors, while maintaining signal integrity is also a priority.

Design and Construction: Engineering for Underwater Challenges

Designing and constructing submersible cables entails a meticulous engineering approach that addresses the unique challenges of underwater environments. Specialized materials are paramount to ensure cable durability and performance.

Water-resistant insulators and jackets are integral components in submersible cable construction. These materials, often made from advanced polymers like polyethylene or polypropylene, create barriers that prevent water penetration. This feature safeguards the cable’s internal components, such as conductors and insulating layers, from the potentially damaging effects of moisture.

Corrosion-resistant metals and coatings are employed to extend the cables’ operational lifespan. Stainless steel, aluminum, and other alloys are chosen for their ability to withstand the corrosive properties of saltwater. Additionally, coatings like zinc or polymer layers act as protective shields, guarding against the corrosive impact of underwater exposure.

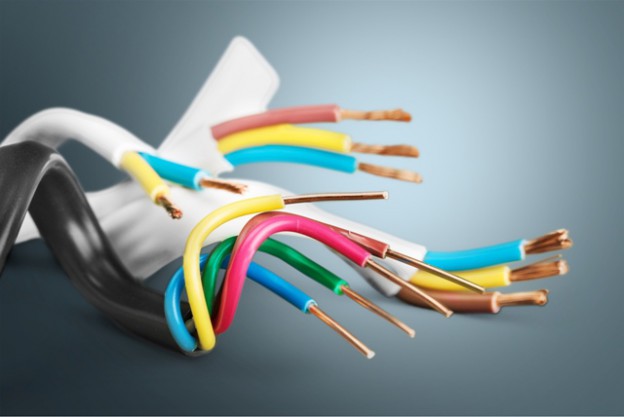

The layered design of submersible cables offers multifaceted protection against mechanical stress and external elements. These layers typically include a central conductor for transmitting electrical signals, surrounded by insulating materials that safeguard the conductor from electrical interference and prevent short circuits. Over this, an armor layer or protective braid enhances mechanical strength. Finally, the corrosion-resistant jacket encases the cable, shielding it from water and other environmental factors.

Waterproofing Techniques and Sealing Mechanisms

Waterproofing submersible cables requires a combination of innovative techniques and sealing mechanisms to safeguard against water ingress and maintain cable integrity.

One approach involves utilizing double jackets with fillers and binders. These jackets consist of multiple layers of water-resistant materials, fortified with fillers and binders that create effective barriers against water penetration. This method enhances the cable’s resistance to external moisture and reinforces its overall structural integrity.

Filling compounds play a crucial role in preventing water ingress along the cable’s length. These compounds are injected into the gaps and interstices within the cable’s core, displacing air and forming a protective seal. By filling voids and potential water entry points, these compounds effectively enhance the cable’s waterproofing capabilities.

Tight seals at connectors and terminations are vital to maintaining overall cable integrity. Specialized sealing mechanisms, such as rubber gaskets, epoxy resin encapsulation, and heat-shrink tubing, are employed to prevent water from infiltrating the cable through vulnerable points. These seals ensure a reliable barrier against water and other environmental factors, minimizing the risk of signal degradation or cable failure.

Shielding and Data Transmission in Aquatic Environments

In aquatic environments, effective shielding and data transmission techniques are essential to ensure reliable communication and prevent signal degradation.

Shielding plays a critical role in safeguarding against electromagnetic interference (EMI) that can disrupt signals. Techniques such as twisted pairs and braided shields are employed to counteract EMI’s adverse effects. Twisted pairs reduce interference by canceling out electromagnetic fields, while braided shields act as protective barriers, deflecting external EMI from penetrating the cable.

To maintain data transmission efficiency, high-quality insulation is employed. This insulation not only protects against EMI but also preserves the integrity of the transmitted signals. By minimizing signal loss and distortion, high-quality insulation contributes to clear and accurate data transmission.

Fiber optic options are gaining prominence for underwater communication due to their ability to transmit data over longer distances and with higher bandwidth. These cables use light signals instead of electrical signals, which are less susceptible to interference and provide greater data capacity.

Conclusion

Submersible cables stand as remarkable feats of engineering, conquering the challenges posed by underwater environments. Their specialized construction, utilizing water-resistant insulators, corrosion-resistant materials, and layered designs, enables them to thrive under water pressure, corrosion, and other environmental factors. By incorporating waterproofing techniques like double jackets, filling compounds, and tight seals, these cables achieve a level of resilience that ensures their continued functionality in aquatic settings.

The significance of shielding cannot be overstated, as it guards against electromagnetic interference and sustains data transmission quality. Techniques such as twisted pairs, braided shields, and high-quality insulation fortify the cables’ capacity to convey accurate information across underwater distances.

As technology advances, the integration of fiber optic options further elevates the potential for high-bandwidth communication in aquatic environments. With each innovation, submersible winding wire cables reinforce our ability to explore, research, and communicate beneath the waves, unlocking the mysteries of the deep sea and expanding the frontiers of underwater knowledge and connectivity.