Electrical power cable is a cable that is used for the distribution and transmission of electrical energy. This cable is used for transmitting extra high voltage at places where overhead lines are not viable to be used at places like sea, airfield crossing etc. Electrical power cables are usually installed as permanent wiring within buildings, buried under ground or run overhead.

Construction of Power Cable

The Electrical power cable is made up of various components. The most important parts are as follows:

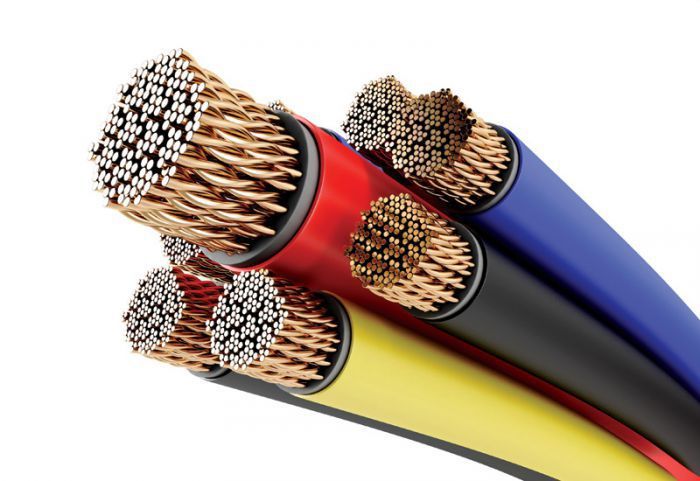

- Conductor: In a power cable conductor is the only power carrying path. It provides the conducting path for the current. Conductors are made up of different materials mainly aluminium and copper.

- Insulation: The insulation or dielectric resists the service voltage and separates the conductor from other objects. It is provided on conductor of a cable by Poly Vinyl Chloride (PVC), Croslinked Polyethyelene (XLPE), various types of Rubber. Synthetic dielectrics are used for submarine and damp soil. These materials are lighter from other and at the same time have good dielectric strength, low thermal resistance, and low power loss.

- Bedding: Bedding or Inner Sheath protects the cable from moistures which might affect the insulation. It is mostly used in multi core cables. It helps in binding insulated conductors together in multi-core power cables. Cable sheath is made up of lead alloy. Aluminium sheath is also used as it is cheaper, and has high mechanical strength that the lead sheath.

- Beading / Armouring (if required): Armouring provides extra mechanical strength and protection to cable. This is done by placing G.I wires, steel strips one by one on the inner sheath.

- Outer Sheath: The outer sheath is the outermost cover of the cable. It is normally made of PVC, various types of Rubber, or may be of the same material as the bedding. It is provides for overall weather, chemical, electrical, and mechanical protection.

Types of Wires

- Triplex Wires: Triplex wires are mostly used in single-phase service drop conductors.

- Main Feeder Wires: Main Feeder Wires connect the service weather head of the house. These are made with solid THIN wire and the cable installed is usually 25% more than the load actually required.

- Panel Feed Wires: These are usually black insulated THHN wire. It powers the main junction box and the circuit breaker panels.

- Non-Metallic Sheathed Wires: It is mostly used in homes. It has 2-3 conductors with plastic insulation and a bare ground wire. The wires are covered with non-metallic sheathing.

- Single Strand Wires: It also uses THHN wire. Each wire is separate. Also multiple wires can be drawn together in a pipe easily.

Color Codes of Wire

- Black: It is hot wire and is used for switches or outlets.

- Red: It is hot wire used for switch legs. It is used for connecting wire between two hardwired smoke detectors.

- Yellow and Blue: It is hot wire. Yellow wire is used for switch legs to control fan, lights etc. Blue wire for 3-4 way switches application.

- White: White wires are always neutral.

- Green and Bare Copper: Green and Bare Copper wire are only for grounding.