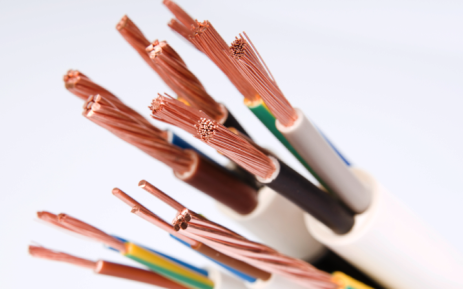

Copper wires are most preferred when it comes to making electrical products and appliances. The copper wire has been a popular choice because of the many advantages it offers compared to other types of wiring. Before you buy copper wires from any online supplier, it is however advisable to check for their reputation. You need to make sure the supplier offers only high-grade superior quality copper wires that are safe for use. They should ideally have buyer-friendly return and exchange policies so that any damaged or defective product can be returned and replaced immediately.

- The biggest reason to choose copper wires is because they are by far the best conductors of electricity. So, it is faster and more effective when you choose copper wiring rather than any other type of wiring.

- Copper wires are also highly flexible by nature and this works to the advantage of those working with these wires. This feature is especially useful when you need to use wires for household purposes. In such situations, it is important to choose wires that can be conveniently twisted and bent to negotiate sharp bends and corners. However, although these wires are very malleable it does not mean that they are easily breakable. They have high ductile strength and will not break or lose their toughness because of bending or twisting.

- Copper wires are ductile and can easily be used for producing very thin wires which are easily bent. These wires are thinner than hair strands and are moldable, but there will be no breakage in the process. They are therefore versatile in nature; you can use them to make thin wiring for headphones and bend them to produce thick cables.

- Another important advantage of using copper wires is that they have a high melting point and this makes them very safe for use. If there is an electrical surge or an overload, it will not melt the wire or burn it. So, the possibility of there being a fire outbreak is minimized when you use copper wiring.

- Maintenance and repair work is less with copper wiring. These do not come off easily; so, you will not have to be worried about them getting loose and falling off. Other metals may have the tendency of loosening after a while and when they get detached, the effects can be disastrous.

- Finally copper wires are always compatible with products which have copper in them. When you use a non-copper wire with a copper wiring, there may be a galvanic action. This may be hazardous and may end up destroying the copper wire which was going to be fixed. So, your repair costs would escalate dramatically. This is why it is always better to use copper wire from start to finish so that there is no compatibility issue.

These are the main reasons why working with copper wires is always safer and easier. They are excellent conductors of electricity but they will not be able to withstand surges. Copper is also susceptible to electromagnetic interference which may cause some equipment to malfunction. This is why it is not recommended for telecommunication devices. Here, fiber optics is found to be a far better alternative.