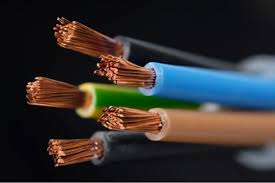

For wires and cables manufacturers use mostly copper as a metal. This has become a trend in the entire globe. This is a fact that United States of America uses 60% of copper wire and cables along with copper-nickel and copper-iron alloy for best electric conductivity. Manufacturers think that if alloy can happen with the right proportion then the usages get double. So, cables and wires manufactures have started experimentation regarding alloy of different metals while manufacturing wires and cables. Continue reading

Ask for Nickel Copper Wire Next Time!!!

Copper is considered as one of the metals which are been used in electrical engineering. When nickel copper alloy happens, it turns out to be one of the toughest metal and the usage gets doubled easily. If you are wandering that what are the usages of a nickel copper wire, then you have landed on the right blog. Yes, here in this blog we are discussing about the benefits and variety of usages of nickel copper wire.

The best part of the nickel copper alloy is that it serves too many engineering products and amenities. For an example, if you own a car or a house, each and every amenity must have the usage of nickel copper alloy. It is a fact that the street lights in several metropolitan cities also need the nickel copper wires. So, we can easily say that there are several usages of this type of wire and thus, there are many manufacturers who have started working on producing this type of wires and that too with right proportion.

The main reason why copper is the right metal because it has great conductivity after silver. It also has the durable tensile power. Manufacturers think that it is the easiest metal to machine. There are many specialties of wire and cables. These are basic reasons why copper is one metal that is used to alloy with other different metals for the best electrical performance. Copper matches the strength with metals like brass, nickel, silver or bronze.

Avail Braided Copper Strip To Enhance the Life of Your Machine

There is no doubt that a copper wire is the best for electrical components. Electrical equipment like turbine, generator, and transformer are to name a few which cause vibration on the electrical distribution joints. To escape these kind of electrical vibrations braided flexible connectors jumpers are been used. These kind of connectors are been used in mainly electrical power industries, industrial factories and in mainly other electrical substations. So, if you are thinking that where to get these kinds of especial connectors jumpers, then you have landed in the right blog.

Yes, in this blog I am discussing about best quality braided copper strip and how it can be useful for reducing any kind of electrical synchronization. Not only that, it is known to all that generators vibrate a lot while running. So, to lessen these kinds of vibrations, the manufacturers use braided flexible connectors jumpers which resolves several problems within the machine and help in smooth running. What more can you ask for?

If sources are to be believed, it has also been said, that braided copper strip is the reason for smooth functioning of these machines. Special copper wires also accelerate the speed of the machine. These improve and enhance the life of the machine that ensures about the long run of the machine. Isn’t that great?

So, if you are thinking to expand the life of your machines then it is on you which parts and wires you select. All generator, turbine and transformer manufacturers should opt for this especial copper wire and now.

Different Usage of Copper Wire!

Copper wires are meant for multipurpose usage. It is a fact that these different purposes require one particular type of wire. This is one unique type of wire is also considered as a unique kind of insulated wire.

Why copper is an important metal to design a wire?

Copper is one metal which is also considered as one of the main electricity conductors. of electricity in a lot of wiring ever since the birth of the telegraph in the 1820s. Because of the many uses for it, different wiring types have been constructed for each use over the years, many of which I’m sure I’ve used more than I remember. For example, there is a fairly large difference between wires used for automotive, telecommunications and appliances. There are a lot of types that serve different purposes such as copper wire cables and braided wire, just to show you how we’ve messed with this technology through the centuries.

General Uses

Used for buildings and homes, there is almost nothing copper can’t conduct. In fact, copper is so prevalent in homes and businesses that buildings can simply be labeled “all-copper” to signify that every wire running through the structures is comprised of copper. From circuit breakers to heavier appliances, copper is a major material used in just about every area of the home. That’s how reliant we are on this stuff. Forget about if the Internet disappeared; if copper did now, we would still be in a lot of trouble.

Speaking of the Internet, copper wire can also be found in computer system mainframes. Because of its versatility, its ability to be solid, stranded, or even braided makes it useful for just about any application imaginable. Each use can benefit from a uniquely produced wire type.

Household Integration

You know the back of your T.V.? The F connector coaxial cable connected to it may seem to be disguised to look nothing like copper, but if you look in the center of the plugging end you can see the copper wire poking out.

Copper is also used in a ton of other electronics, like telephones and computers. Structured wiring is the use of modern day copper wiring to connect computers to each other so they can have a high speed connection. Structured wiring is used for connecting computers to other devices as well such as printers and fax machines. Ethernet cables use it, and I guarantee most of your appliances anywhere in the home use it, from your washing machine to your microwave.

Most copper wire cables are either solid or stranded. Stranded is more flexible but both are really conductive. Braided wire is used not so much for electrical purposes, but to coat and support other wires. When braided, copper is really flexible, and at the same time tough. You can even coat your hoses with it to keep them from bending and tearing.

Key Advantages of Copper Flexible Connectors

Copper braided flexible connectors are particularly fabricated for providing maximum flow of electrical power with superior competency. Personalized designed on a large scale to regulate the machine delivered vibration, retrenchment and extension with a value-added resistance.

braided flexible connector jumpers

Copper flexible connectors are widely used in computers, electrolytic processors, transformers and power generators. These flexible connectors are majorly applicable in planting and communication industry as well.

The braided flexible connectors are well known because of its flexibility and extended functional life. However, according to the requirement concern the copper braided connectors can be designed with silicon sleeves, sleeves that contracts when heated and even sleeveless.

Moreover, these copper braided flexible connectors are meant to provide the required flexibility in the piping system, detain noise and unnecessary vibrations created. This further allows the usual movement of the other components to make up for the thermal growth.

Braided Flexible Connector Jumpers have just the right wall thickness to reduce the stress within the piping system. In order to lessen the level of the automatically generated noise, the vibration has to be minimized. This can be done with the assistance of these exceptionally designed malleable connectors made out of copper braided wire.

These types of connectors are exclusively designed, bearing in mind the purpose for which they will be used. Made from electrolytic copper foils, loaded one above another in numerous films which are passed through extreme pressure and current. These connectors can easily withstand the upheaval within the machines and switch gears.

In fact, the copper braided flexible connectors are just the best option for attaching bus-bar, bus-ducts, and electric locomotives and so on. Aluminum is another significant alloy that is commonly used in fabrication of flexible connectors besides copper.

Hence, copper braided flexible connectors jumpers have its own exclusive qualities that makes it most preferred item. Make use of copper made connectors and stay rest assured.

Tinsel Copper Wire for Maximum Mechanical Flexibility!

Electrical equipment should of great quality of high performance. Whether it is a residential or a commercial project, the electrical wire has to be of a grade. Electricians or the wire experts always focus on one of the major requirements and that is the high electrical conductivity. Mechanical engineers prefer to use copper wire these days. Copper is one of the most used metals for electrical wire manufacturing. Copper displays the best conducting properties and thus it is one of the basic choices for manufacturing and using into the electrical wires and cables. The other reason for using the tinsel copper wire is the utmost security.

There are lots of other electrical equipment which are been used for residential and commercial buildings. Copper wires are efficient for immense electrical conductivity and people also prefer using braided flexible connectors jumpers for several electrical usage. Now days the usage of enameled copper strip is also there and these strips are for multipurpose usage. Tinsel copper wire can be used for various applications in the power transmission. These are also used for power distribution and in the telecommunication sectors. Thus, we can see that the usage of tinsel copper wires and copper strips in several fields.

In today’s day and age, electricians are well read and are skilled and use different equipment to meet the requirements. With the technical advancements, there are ample of equipment which is available in the industry. Copper, the metal is one of the best options and it can be alloyed easily with other metals as well. These metal mixtures are for improved properties and unique wires that can offer better electrical conductivity.

Here we can speak about some of the useful characteristics of tinsel copper wire. For example, it offers high tensile strength and ductility. An enameled copper strip has the creep resistance and best for thermal expansion. People also choose copper wire for corrosion resistance and thermal conductivity. There are the main factors why people are opting for copper wires and skipping other metal wires. Hope this blog serves the purpose of using different copper wire and the usage on different industries.

An Understanding of Bare Copper Wire

Wires or cables are used to transmit energy. One of the popular types of wire used is bare copper wire owing to being a good conductor of electrical energy. It’s majorly used to ground electrical systems and can easily be purchased in solid or stranded type or in soft or hard wired.

What is a Bare Copper Wire Composed of?

Bare copper wire is a single stranded wire that is annealed for high ductility and meets QQ-W-343 standards for uninsulated copper wire. It consists of copper with small amount of Copper Oxide impurities.

Making of a Bare Copper Wire An electrical wire carried electric current, which is proportional to its gauge size and is coated with some metal to insulate. Another objective to coat the wire with a metal is to safeguard it against moisture, chemicals, heat, corrosion and abrasion. Copper is the most frequently used metal for electric wire, but is sometime mixed with alloys to offer better strength and resistance to the wire. A wire can either have a single strand or multiple smaller strands, depending on the supplication of the wire.

Application of Bare copper wires play a critical role in the manufacturing of overhead transmissions and distribution applications, whereas stranded conductors are generally used for uninsulated hook up, jumpers, and grounds. It is also well suitable for the making of the wires used for electrical grounding.

Braided Copper Wire and its Properties

Copper has been regarded as one of the most important metals in the history of mankind. Various alloys as well as products related to copper have been manufactured and widely used round the world across various industrial segments. Copper braided wire and tinned copper from India have been utilized by the industrialized in large amounts.

Copper braided wire has been used wherever large flexibility is needed; since it is known to be much stronger than the solid copper wire it has the ability to withstand more weight. Copper braided wire is used across electrical cables and speaker wires for headphone cables and appliances. The thickness of this kind of wire is varied. It can be used as thin wires in ear bud headphones and thicker when used in overhead power lines.

Copper strip manufacturers and copper wire manufacturers of India produce this kind of copper through high conductivity ETP grade Copper wire with diameter ranging from 0.07 mm to 0.30 mm.

Tinned copper India is another category which is available at highly economical prices. The tin coating provides copper wire excellent anti-corrosion as well as soldering benefits. It has very flexible dimension and has the ability to retain the overall flexibility. Moreover copper is available as tinned, un-tinned or silvered copper

Copper and Aluminium- Common Electrical Application

Copper and aluminium are the two metals that are mostly widely used for electronic application. The wires drawn from these metals are preferred for both residential and commercial wiring. Copper is considered to be purest variety among other alloy metal and is the best conductor of electricity as well. Continue reading

PVC Coating- Increasing the Applications of Copper Wire

PVC coated wirehave great importance in various domains. They are utilized widely for commercial purposes like building chain link fences or cages; they are also used in making tennis courts, freeways as well as safe electrical wirings.

They come in a variety of colors and sizes and are used in non-aerospace applications.PVC Coated Wire often comes with test certification. It is easy to strip as can have almost any base color. Their use as a coating for security cables is very popular.

PVC coated wire can be a PVC coated iron wire or even a copper wire.Bare Copper Wire often comes with hazards of sudden fire or electrical shocks. They are coated with PVC in order to increase resistance and reduce chances of fire. They are corrosion resistant and are also known to have anti-aging property as a result they are known to give a better service life than a common galvanized wire.

Copper manufacturers producing various products such as Copper Flat Wire, Bare Copper Wire, Copper Foil, etc. also produce PVC coated varieties in orderfor use in electrical and electronic domain.

PVC coating is also known to be wear-resistant, cold & oil resistance as well as anti-ultraviolet. They are also used in areas with moisture as they are waterproof. Hence PVC has an important usage in making copper wire safe and more usable.