The aluminum rod is known for offering a high degree of resistance to corrosion and weldability, making it popular for electrical goods manufacturers. Besides, the high strength rods can also be used in making aerospace applications. The corrosion-resilient aluminum round rods are ideally suited for marine applications because these are exposed to water all the time. Continue reading

Author Archives: info@rajasthanelectric.com

Why tinsel copper wire the most preferred metal?

Tinsel wire is a low voltage electrical wire that is used mainly where high power-driven flexibility is essential. Generally speaking, it is most commonly used in the wires that are used in telephones, particularly the handset cords, and in headphones. As tinsel wires are quite malleable it is resistant failing because of metal fatigue relatively to normal stranded wire or solid wire. It is usually made up of copper.

Tinsel Copper wires are used in different industry rather being restricted to electrical industry. These wires first undergo a processing through tinsel tin, tinsel Silver, silver platted copper, cadmium copper and electrolyte copper. During this processing procedure these wires are flattened and covered with thread, including cotton, nylon, silver, nomex and Kevlar. But, this all depends on the requirement of the customers.

Let’s have a quick glance at the key applications of tinsel copper wires:

- It is largely used in the fabrication of Speakers

- It is extensively used in the manufacturing of Loudspeakers

- It is used in the Tweeters coils

- It is also used in the creation of Telecom cable

There are numerous of manufacturers that are manufacturing different types of Tin coated copper wire, and tinsel copper wire. Try to look for the right supplier!

Why are Copper Wires better than Iron Wires?

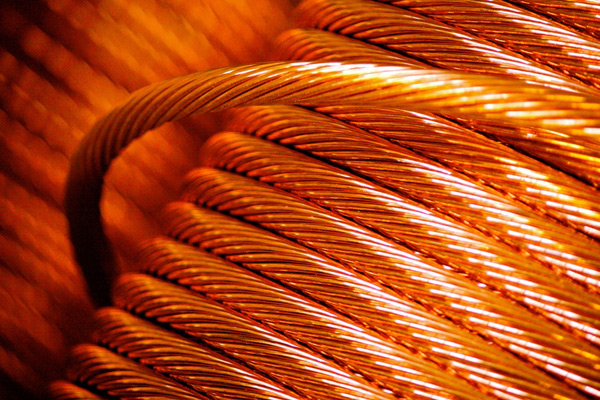

Copper wires have been considered as one of the most preferred choice for electrical wiring mainly due to the fact that it has high electrical conductivity comparatively to other metals. High conductivity of copper actually ensures smooth passage of electricity through it without being getting much heated up. These wires are basically raw material that is used by the Cable Industries for fabrication of different types of wires.

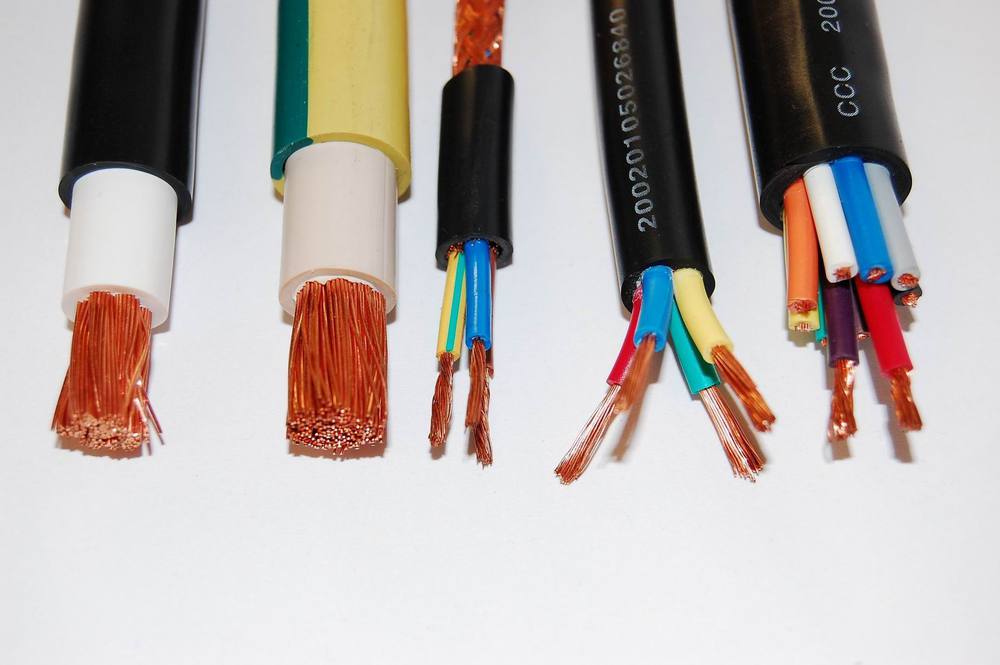

In fact, there are some of the electrical power cable that are created from copper include, tinsel wire, submersible winding wire, copper strip, special cable and control cable to name a few. Furthermore, this copper wire manufacture is even carried out for the creation of several other instruments and machines.

While other metal used in fabrication of power cable is iron. PVC coated and insulated wire made from this metal is widely known plastic for the coating of electrical wires. It is comparatively more fire retardant low in resilient, cost and also has exceptional insulating properties.

Wires made from these metals have become widely known as they wires made from both types of metal are used for the residential as well as commercial wiring. Some of the key features of copper that gives it an upper hand over the other types of metals is that it is highly elastic and known to have high resistant against metal corrosion.

Robustness and ductility of this metal make it possible to fabricate them into different shape and size in a very expedient manner. Moreover the robustness aids copper wire withstand any type of climatic condition ranging from extreme heat to extreme cold.

Where will you use the Stranded Wire?

The stranded wire is found to be far more flexible compared to the solid core wire that is of the same size. Moreover it is more useful in case you need a wire which has to be moved around often, for instance, like the wires in a robot arm. The solid wire, in comparison will be used where there is no demand for a lot of movement like the circuits on breadboard.

When you are choosing the type of wiring for any electrical project, you will have to look at many important factors. Depending on the kind of application you want and the amperage, you need to choose the right gauge and the kind of metal wire which will be best for the task. The wiring expert therefore tries to see the differences between the stranded wire and solid wire too when it comes to choosing the right wiring for the project.

Where will you use the stranded wire?

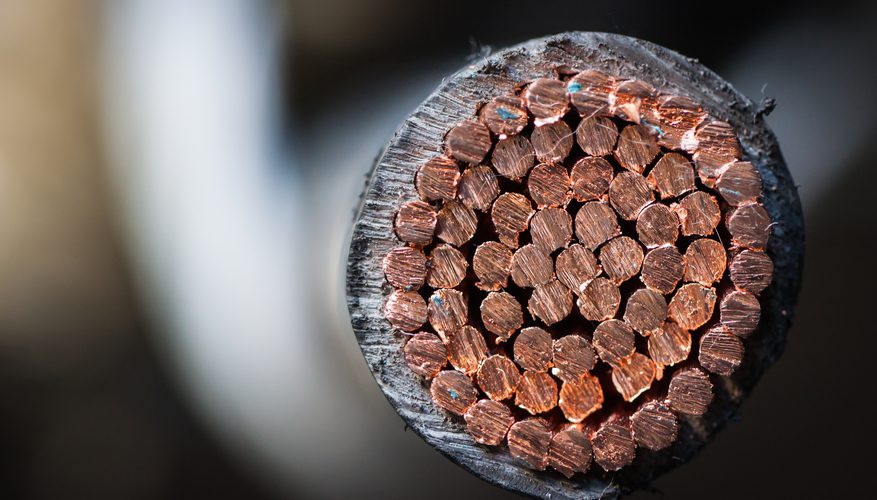

The solid wire is going to have one metal core while a stranded wire will be made up of many thin wires that are braided or twisted together to make one cohesive bunch of wires. Both these kinds of wires can be used for both domestic and commercial usage but each has its strength and weaknesses which help us decide on the right one for the application at hand. This is why the solid wire is typically used for all rugged-duty applications and outdoor uses where such wires are likely to be exposed to very adverse climatic conditions. The stranded wire, however, will be used more for intricate and sophisticated uses like in circuit boards and electronic devices. Here the wires are going to be well protected even though they may be twisted or bent while connecting them to electronic components.

There are many advantages of using the solid wire, the main ones being simplicity of use, durability and costs. Since the solid wire comprises of only one metal core, the chances of damage to it are less. But, when you must use these for bending and twisting like in the making of circuit boards the stranded wires are the best. They are most often used for vehicular applications and for robotics. Here, the solid wires are of no use because they do not have the malleability or strength to withstand such reshaping or frequent movements. The stranded wire is the best possible option for applications where a lot of lot of reshaping is needed. This wire is however not very good for preventing electronic interference since air channels in between these strands can increase skin effect which is triggered by the magnetic fields on wire surfaces.

Where costs are concerned, it is necessary to see the costs in the long term. The solid wire for instance will require less upfront investment as compared to the more expensive stranded wire. But the latter will last much longer in places where there is a lot of reshaping of wires and frequent alternations. The bare stranded copper wire gets made from electrolytic grade copper. It is therefore important to choose a manufacturer which complies with global quality standards when it comes to making products from such wires.

The submersible cable has been designed specially to work in marine environments. This is because this cable is known for providing electrical power even in wet conditions. The main reason why it has been able to do so is because of its rubber and plastic coating. This plastic coating allows the cables to withstand all liquid substances like oil, water or grease. The submersible cables have robust mechanical and electrical properties which can protect them from oil or water. Such cables can be found in single or multiple conductors. Their shapes or sizes will differ according to the applications for which they are used. They are mainly used for power conductors for pump motors. Besides, these cables can also be used for irrigation systems, underground mining, and drilling works. When identifying a manufacturer for buying these cables, it is important to check their credentials and reputation. You need a manufacturer which can offer you quality products at affordable rates and which have a buyer-friendly return and exchange policy.

Why is Copper Flat Wire So Important

Copper wires are the most reliable and popular for use in electrical appliances and goods. It is the favorite for the electricians and technical people dealing with any type of wiring. People have always been used to the round wires and cables having been used since ages. However, as technology developed, the need for something more flexible arose. The copper flat wire was development sometime close to the mid-20th century to address this requirement. This brought about significant changes in the way copper wires could be used ushering in ease of use, improved performance, reliability, and wider acceptance.

Why copper

1. Copper is the most used element in various industries like in the construction as plumbing, electric wiring, roofing etc. There are various reasons for people relying on copper for electrical purposes. These include

2. Copper is an excellent conductor of electricity. Only silver surpasses copper in terms of electrical conductivity, but it is expensive on one side and does not have so many attributes.

3. It is robust, resistant to abrasion, heat resistant, and can withstand adverse climatic conditions. There is a frequent rise or fall in the temperature in electrical lines. Copper can sustain fluctuations.

4. The metal is durable, flexible, and very ductile. It can be stretched, molded into any form, and still retain its strength.

5. Copper is available in different forms and is mixed with other metals to form highly efficient alloys. It can be customized and used as per your needs for connectors, braided tapes, cables etc.

Copper flexible connectors are made from silver-plated, tinned, and bare copper wires. Several industries depend on these connectors for use as joints to connect bus bars. Foils of electrolytic copper are stacked together, and electric current is applied under high pressure. They are widely applied in VCB, bus ducts, switchgear industries, resistance welding engineering, power plants, electric locomotives etc.

What makes flat wires and cables popular:

Versatile and reliable

There are numerous ways the copper flat wire is used for wiring needs such as low-voltage lighting, data, audio, video, HDMI, and highly efficient in streamlining a worn-out home theatre system that requires revamping. Flat wires adapt very well to all types of surfaces. They can be installed easily. You just need to push and press, it sticks firmly. You can bend it, fold it, stretch it, use it anywhere without worrying about its strength or durability. it removes all the complications that are associated with the round wires and cables.

Weight saving

The use of flat wires often reduces the overall weight of the product. Tapes, fillers, insulation etc, adds up to the weight of the product. It is strong by itself and does not require any large conductors for strength. The current load can be carried with much lower cross-sections managing voltage drops.

Flexible

Applications that require movement like drawers, Axis-control equipments, medical diagnostic appliances, robotics, doors, rotating arms, and similar need flexibility in all the tools. The way the copper flat wire can be bent and applied with minimum wiring errors while eliminating malfunction risks.

High-Density Interconnections

Flat wires achieve better cabling density than the normal other conventional cables. They are more effective for higher conductor applications than the round wires or cables.

Space optimization

When the need of fillers, insulations, tapes etc., is not there, it automatically reduces not only the weight but creates more space for the copper flat wire. It can be stacked and layered in any manner ensuring there is no wastage of space.

How to choose the copper flat wire when coating is required

The above-mentioned properties define the flexibility and suppleness of the flat wires. This increases its usage among different applications. Certain applications require maximum flexibility. So, it is important to check the shielding material that is being used. The conductor must be left open or have exposure rather than be under cover to ensure strong bonding. It will also reduce the risk of conductor movement. Alignment is preserved when the movement is lessened. Silicon rubber should be tried as they can provide more flexibility than the PVC insulation. It is necessary to ensure the jacketing material must be hard and should not succumb to wear and tear while in motion.

How to Choose your Wire Manufacturers

It is not necessary that a cable and wire manufacturer has the same capability as the other manufacturer. Their services may differ based on the size, dimensions, price, and of course quality. The wire manufacturers differ in their expertise and finding one who has the capabilities to provide products as required by you can be time-consuming unless you are ready with the information they would require, and you are prepared with your questions.

What you must know about your requirements:

1. The design: Determine the type of wire you need, whether you need it to for a new setup or is there a previous existing design that you need to improvise. If it is the latter, you must inform the suppliers when it was installed, its cost, brand, and the quality. If it is for a new setup, ask for quotes from different wire manufacturers, negotiate, check for quality, their ability to scale in case you require more, the return policy for any leftover material etc.

2. Technical points: This might include the power the cable needs to deliver, number of contact points, voltage, grounding, the type of signal, its speed, the type of connectors you will need etc. If you are sure of what you need, it will save plenty of time and money. In case you are not comfortable with the technicalities, the manufacturers have their specialists who can help you determine and provide a customized solution.

3. Quality concerns: It is important for you to inform the manufacturer the purpose and where you will be using the wire. While most of the wire manufacturers use copper because of its amazing properties, you must make sure they are corrosion -resistant, durable, can withstand heat, moisture, and other calamities. These are the general requirements. If your requirement is for some hospital or health concerned, the equipment may need frequent sterilization or washing. Such specific points must be informed in advance so that they build the product accordingly using different technologies.

Why wire manufacturers prefer copper

Copper, as mentioned, has many remarkable properties.

- It is a good conductor, can be molded in many ways, and is far less expensive than silver, the other metal which offers superior conductivity.

- Wires are used everywhere- overhead, underground, in buildings, external wiring and in almost all electrical and electronic items that requires wiring.

- Copper is durable, robust, and gives longevity to all products it is used in. It can sustain all types of extremities- heat, rain, any other outage without causing any risks to life.

- Copper is either used in its raw form or at times, mixed with other elements like aluminum, nickel, lead, tin, and more.

Manufacturer’s Certifications:

Almost all manufacturers are available online with their website. They display their licenses and certifications in a prominent corner or in the About Us page. This is practically seen in every business website with licenses and certification from their respective industries. For the wire manufacturers the most important certificate is the ISO (International Organization for Standardization). It is recognized all over the world and applies to most industries. The certificate ensures the reputation of the supplier. It confirms that the products are of high-quality and they meet all the safety measures that are required. This is important since you are talking about products that can cause fire and destroy both property and lives. In India there are other registrations to be done like the SSI and NSIC.

Because they maintain the quality and safety standards most of the manufacturers and supplier have their clients from the international market. The Indian copper manufacturer usually carries a copper wire exporter license. They have an IEC code number and is a registered member of the Federation of Indian Export Organization (FIEO). They ensure the material they supply is tested several times before it is released into the market.

Industries where copper wire is vastly used

The competition is growing in the wire manufacturing industry. The wire manufacturers while ensuring the quality cannot afford to price their products high. Copper wire is used in the making of biometric scanners which nowadays are important for identification while entering most of the places that require high security. It is used in industries like telecommunication, aerospace, defense, and every electrical appliance used in homes.

Why is the Bare Copper Strip Preferable?

The bare copper strip is extensively used because of its high conductivity. As compared to other metals which are available, copper appears to be the leading conductor and this is why it is invariably the first choice for manufacturers of electrical products and appliances. The bunched copper wire is made up of many strands of copper wires which are braided together. These can also be twisted and tweaked easily and offer many advantages.

Should You Buy the Enamelled Copper Wire?

Since copper is known to have better conductivity compared to aluminum, heat losses will be lower. Aluminum of course is lighter in weight than copper and since its capacity to withstand heat is thrice greater than copper, it can handle current overloads better. You will find that the PVC copper wire can be either flexible or rigid. The latter is mainly used for making pipes, cards, bottles and insulated cables. The PVC copper wire is very versatile, and has high tensile strength; it is a great conductor which is also easy to join. Because of its dynamic properties, such wires can be used for circuits, home appliances, home wiring uses, power supply solutions, mining operations, submarines etc. Continue reading

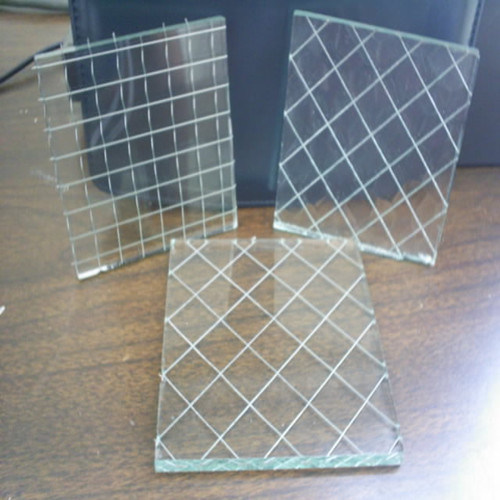

Why Do You Need the Glass Wire?

You will find a variety of wires today, whether it is copper wire, aluminum wire or glass wire, and these are designed to cater to different types of needs. Since there is a multiplicity of industries like marine, aviation, real estate etc, you will also need diverse wires for each of these types. The importance of fiber glass wire in the market has increased recently. The way these glass wires are produced is much different from the ways in which other kinds of wires are manufactured.

Why You Need Nickel Copper Alloy?

There is a lot of demand for the nickel copper alloy which is mainly used for marine application. The reason behind using the nickel copper alloy in such cases is because the alloy is highly resistant to marine water corrosion. These alloys continue to provide an effective solution for all kinds of technological challenges today. When nickel is added to copper it can improve its strength and resistance power to corrosion. At the same time, the alloy continues to be ductile. You can even add other materials to such alloys to enhance its robustness, corrosion-resistance, castability and weldability. Like the nickel copper alloy, the PVC wire is another product which is becoming popular for wiring for safety reasons.