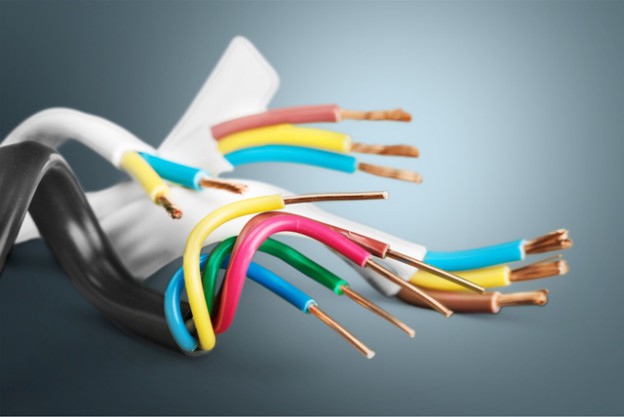

Copper has long been the backbone of electrical and industrial systems due to its excellent conductivity, durability, and flexibility. Today, the demand for high-quality copper products continues to grow across power transmission, electronics, automotive, renewable energy, and infrastructure sectors. A reliable Copper Wire Manufacturer plays a critical role in supplying precision-engineered copper solutions that meet both domestic and global standards.

Importance of Electrical Copper Wire in Power Systems

Electrical Copper Wire is widely used in residential, commercial, and industrial wiring systems. Its low resistance and high current-carrying capacity make it ideal for efficient power distribution. Whether used in control panels, transformers, or motors, copper wires ensure stable electrical performance and long service life. Modern manufacturers produce different grades and forms of Copper Wires to match specific voltage, temperature, and mechanical requirements.

Stranded and Flat Copper Wire Applications

Stranded Copper Wire is designed for flexibility and vibration resistance, making it suitable for applications where frequent movement or bending is required. It is commonly used in automotive wiring, industrial machinery, and portable electrical equipment.

On the other hand, Flat Copper Wire offers a compact design with improved surface area, which enhances heat dissipation and current flow. Flat wires are increasingly used in power electronics, busbars, transformers, and renewable energy systems.

Copper Braided Wire and Braided Connectors

Copper Braided Wire is widely used for grounding, bonding, and EMI shielding applications. Its braided structure allows excellent flexibility while maintaining high conductivity. These wires are essential in switchgear, railway systems, and heavy electrical equipment.

Similarly, Braided Connectors provide reliable electrical connections where vibration, thermal expansion, or movement is present. They ensure consistent current flow and reduce stress on rigid conductors. Products like Braided Copper Rope are commonly used in earthing systems and lightning protection installations.

Copper Laminated Flexible Connectors

Copper Laminated Flexible Connectors are manufactured using multiple thin copper foils laminated together. This design reduces skin effect losses and improves flexibility compared to solid connectors. These connectors are widely used in transformers, power distribution units, battery systems, and industrial drives where high current transfer and flexibility are required.

Bare Copper Strip and Enamelled Copper Strip

A Bare Copper Strip is an essential component in electrical panels, grounding systems, and busbar applications. Its high conductivity and ease of fabrication make it suitable for custom electrical designs.

In contrast, Enamelled Copper Strip features an insulating coating that allows compact winding and improved electrical isolation. These strips are commonly used in transformers, inductors, and electric motors, where space efficiency and insulation reliability are critical.

Tin Coated and Silver Copper Wire

Tin Coated Copper Wire offers enhanced corrosion resistance, making it ideal for marine, outdoor, and high-humidity environments. The tin coating also improves solderability, which is essential for electronics and communication systems.

Silver Copper Wire combines the conductivity of copper with the superior surface performance of silver. It is used in high-frequency applications, aerospace systems, and precision electronics where minimal signal loss is required.

Tinsel Wire for Flexible Applications

Tinsel Wire is specially designed for applications requiring extreme flexibility. It consists of thin metal ribbons wrapped around a textile core, making it ideal for headphones, robotics, medical devices, and moving electrical components. Tinsel wire reduces metal fatigue and ensures long-term reliability in dynamic environments.

Copper Strip Manufacturer and Export Capabilities

A trusted Copper Strip Manufacturer focuses on precision rolling, uniform thickness, and strict quality control. Copper strips are used in electrical contacts, connectors, heat exchangers, and power distribution systems. Manufacturers often offer customization in width, thickness, and surface finish to meet industry-specific requirements.

As global demand increases, the role of a reliable Copper Wire Exporter becomes vital. Export-grade copper products must comply with international standards, ensuring consistency, safety, and performance across markets. Exporters supply a wide range of products, including Copper Braided Wire, Bare Copper Strip, and Tin Coated Copper Wire, to industries worldwide.

Quality and Innovation in Copper Manufacturing

Modern copper manufacturing emphasizes advanced production techniques, strict testing procedures, and sustainable practices. From raw material selection to final inspection, every stage ensures that copper products meet electrical, mechanical, and environmental standards. Continuous innovation allows manufacturers to develop specialized products like Braided Copper Rope and Copper Laminated Flexible Connectors for evolving industrial needs.

Conclusion

Copper remains an essential material for electrical and industrial applications due to its unmatched conductivity and versatility. From Stranded Copper Wire and Flat Copper Wire to Enamelled Copper Strip and Silver Copper Wire, each product serves a specific purpose in modern infrastructure. Choosing a reliable Copper Wire Manufacturer and Copper Wire Exporter ensures consistent quality, performance, and long-term reliability for critical electrical systems across industries.