In the vast world of metal alloys, aluminum stands out as one of the most versatile materials, offering a remarkable balance between strength, weight, and corrosion resistance. For industries ranging from construction to aerospace, high-quality aluminum rods play a pivotal role in the development of durable and efficient products. However, purchasing aluminum rods, especially when you are aiming for top-tier quality, requires more than just a cursory glance at specifications.

In this blog, we delve into the crucial factors you should consider when buying high-quality aluminum rods, with a focus on PVC-coated wire and its integration.

The Importance of Quality in Aluminum Rods

Before diving into the specifics of what to look for, it’s essential to understand why quality matters. The performance and longevity of aluminum rods, whether used for electrical, construction, or automotive purposes, depend heavily on the quality of the material. Low-grade rods can result in poor conductivity, reduced strength, and increased maintenance costs. Therefore, identifying high-quality rods ensures that your project stands the test of time and performs optimally.

Key Factors to Consider When Purchasing Aluminum Rods

Material Composition and Grade

Aluminum alloys come in a range of grades, each suited for specific applications. The two most common alloys used in aluminum rods are 1050 and 6061.

- 1050 aluminum is highly pure, offering excellent electrical conductivity, making it ideal for electrical wiring applications.

- 6061 aluminum, on the other hand, is a more durable alloy with enhanced strength and resistance to corrosion, making it ideal for structural applications.

The grade of the aluminum rod you choose will ultimately depend on the demands of your project, so understanding the difference in alloys is essential for making an informed decision.

Diameter and Length Precision

Precision in the diameter and length of aluminum rods is crucial for ensuring they fit seamlessly into your design. High-quality rods will have strict tolerances in terms of diameter, and their lengths will be consistent, reducing the need for additional adjustments. In projects that require the rods to fit into intricate systems or mechanisms, the accuracy of these measurements becomes even more important.

Surface Finish and Coating Options

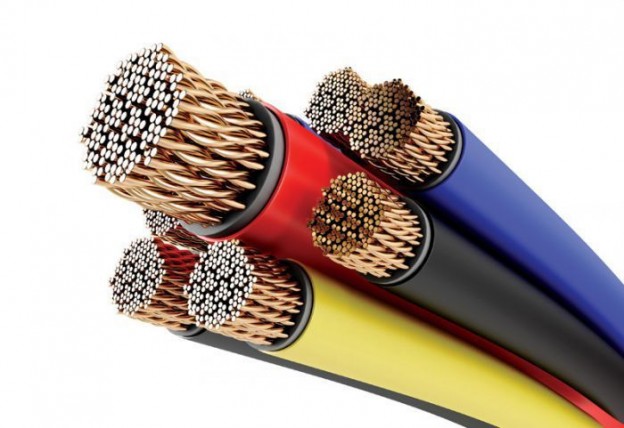

While bare aluminum rods are commonly used in applications where minimal corrosion protection is needed, many projects benefit from additional protection in the form of coatings. One such option is PVC-coated wire, which is designed to prevent corrosion and enhance durability, particularly in environments that are exposed to moisture or harsh weather conditions. The PVC coating also provides an insulating layer, reducing the risk of short circuits in electrical applications.

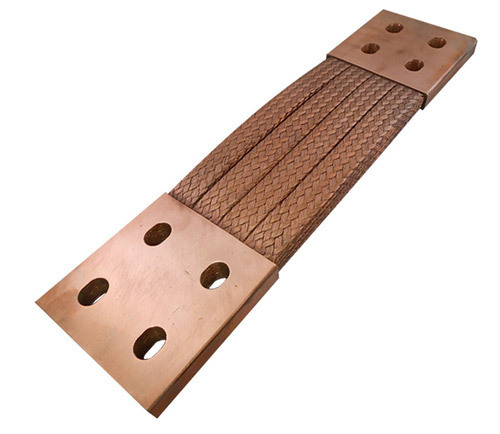

Mechanical Properties and Strength

Aluminum rods differ in their mechanical properties depending on their alloy composition and the methods used during their production. If strength is a critical factor in your project, choosing rods that offer higher tensile strength and better formability will be essential. Testing mechanical properties, such as tensile strength and elongation, can give you an idea of how the rods will perform under pressure and stress. This is especially important when the rods are being used in structural applications or where heavy loads are involved.

Corrosion Resistance and Environmental Impact

Aluminum wire is naturally resistant to corrosion due to the formation of a protective oxide layer. However, the environmental conditions in which the rods will be used may require additional protection. In industries like power transmission or marine applications, aluminum rods often need to withstand highly corrosive environments. In such cases, opting for coatings such as PVC or anodizing can improve the rod’s resilience and increase its lifespan. Furthermore, consider the ecological footprint of the production process, as some manufacturers use more environmentally friendly methods than others.

PVC Coated Aluminum Wire: The Added Advantage

When purchasing aluminum rods for electrical or outdoor use, opting for PVC-coated aluminum wire offers distinct advantages. The PVC coating provides:

Electrical Insulation: Ensuring safety when used in electrical systems by preventing short circuits.

Durability: Protecting the rods from external elements like moisture, chemicals, and UV rays.

Aesthetics: The coating adds an appealing finish, especially in applications where appearance matters.

The use of PVC-coated aluminum rods is gaining traction in industries that demand a combination of strength, corrosion resistance, and electrical insulation. They are increasingly found in telecommunications, energy sectors, and even in construction projects.

Conclusion:

When purchasing high-quality aluminum rods, it’s not just about selecting the cheapest or most readily available option. You need to prioritize material composition, precision in measurements, surface finishes, and protective coatings to ensure optimal performance in your project. PVC-coated aluminum wire is a powerful option to consider for enhanced durability and safety, particularly in electrical or outdoor applications. The key takeaway is that quality should always be your top consideration, as the investment in high-quality rods will pay dividends in terms of longevity, reliability, and overall performance.

Before making your final purchase, assess the specifications based on your unique requirements, and choose a reputable supplier who adheres to industry standards. This approach will help you secure the best aluminum rods for your needs, setting the foundation for successful, lasting results.