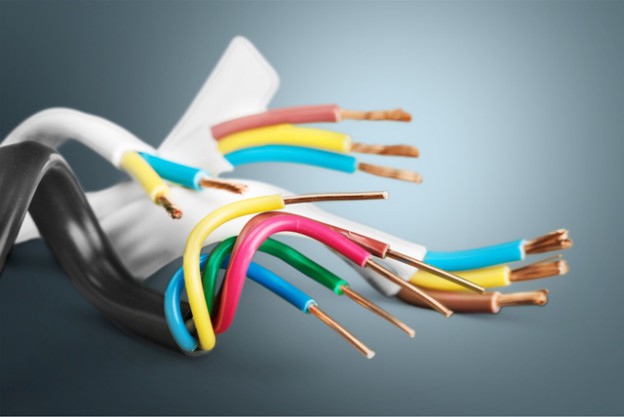

In today’s fast-evolving electrical and industrial landscape, choosing the right wiring and cabling solutions is essential for safety, performance, and long-term reliability. From residential buildings and commercial complexes to manufacturing plants and renewable energy projects, high-quality electrical power cable systems form the backbone of every operation.

Understanding key components such as copper wire gauge, enamelled copper wire, PVC copper wire, and stranded wire helps businesses and individuals make informed decisions. Working with trusted wire manufacturers ensures compliance, durability, and consistent electrical performance.

This guide explores everything you need to know about power cables and copper wiring solutions used in modern infrastructure.

Understanding Electrical Power Cables

An electrical power cable is designed to transmit electricity safely from one point to another. These cables are engineered to handle specific voltage levels, environmental conditions, and load requirements.

Power cables are commonly used in:

-

Residential wiring systems

-

Industrial machinery

-

Power distribution networks

-

Data centers and commercial buildings

-

Renewable energy installations

High-quality power cables feature strong insulation, excellent conductivity, and resistance to heat, moisture, and mechanical stress.

The Importance of Copper Wire in Electrical Systems

Copper remains the most preferred material for electrical wiring due to its:

-

High electrical conductivity

-

Low resistance

-

Excellent thermal stability

-

Long lifespan

-

Corrosion resistance

Whether used in PVC wire, copper strip, or enamelled copper wire, copper ensures efficient power transmission with minimal energy loss.

What Is Copper Wire Gauge and Why It Matters

Copper wire gauge refers to the thickness or diameter of a wire. It directly impacts how much current a wire can safely carry.

Key points about wire gauge:

-

Lower gauge number = thicker wire

-

Thicker wires carry higher current

-

Thinner wires suit low-power applications

Choosing the correct copper wire gauge prevents:

-

Overheating

-

Voltage drops

-

Short circuits

-

Fire hazards

For example, household wiring typically uses thicker gauges than control circuits or electronic devices.

PVC Copper Wire: A Reliable Choice for Daily Use

PVC copper wire is one of the most widely used wiring solutions in residential and commercial projects. It consists of high-purity copper conductors coated with polyvinyl chloride (PVC) insulation.

Benefits of PVC copper wire include:

-

Excellent insulation properties

-

Fire resistance

-

Moisture protection

-

Long service life

-

Cost-effectiveness

PVC copper wire is commonly used in lighting systems, power sockets, control panels, and switchboards.

PVC Wire: Versatile and Cost-Effective

PVC wire refers to insulated wires that use PVC as the primary protective layer. These wires are available in both copper and aluminum conductors, though copper remains the preferred choice for critical installations.

Advantages of PVC wire:

-

Easy installation

-

Flexible structure

-

Chemical resistance

-

Suitable for indoor and outdoor use

-

Low maintenance

Due to its versatility, PVC wire is widely used in homes, offices, and industrial facilities.

Enamelled Copper Wire for Precision Applications

Enamelled copper wire is coated with a thin insulating enamel layer instead of traditional plastic insulation. This allows for compact winding and high efficiency.

It is commonly used in:

-

Electric motors

-

Transformers

-

Generators

-

Inductors

-

Relays

Key features include:

-

High thermal resistance

-

Space-saving design

-

Excellent mechanical strength

-

High dielectric performance

For industries requiring precision and reliability, enamelled copper wire remains an essential component.

Copper Strip: Supporting High-Current Applications

A copper strip is a flat conductor used in applications requiring high current flow and efficient heat dissipation.

Common uses include:

-

Busbars

-

Power distribution panels

-

Switchgear systems

-

Battery connections

-

Solar installations

Copper strips offer low resistance and excellent durability, making them ideal for heavy-duty electrical systems.

Stranded Wire for Flexibility and Durability

Stranded wire consists of multiple thin copper strands twisted together. This design improves flexibility and reduces the risk of breakage during movement or vibration.

Benefits of stranded wire:

-

High flexibility

-

Improved fatigue resistance

-

Easy routing in tight spaces

-

Better vibration tolerance

It is widely used in appliances, automotive wiring, robotics, and portable equipment.

Power Cable Solutions for Industrial and Commercial Needs

A modern power cable must meet strict safety and performance standards. Industrial power cables are designed to withstand extreme temperatures, heavy loads, and harsh environments.

Key features include:

-

Multi-layer insulation

-

Flame-retardant coatings

-

High voltage tolerance

-

Mechanical protection

These cables ensure uninterrupted power supply in factories, data centers, hospitals, and infrastructure projects.

Role of Trusted Wire Manufacturers

Selecting reliable wire manufacturers is critical for maintaining safety and compliance. Established manufacturers follow international standards such as IEC, IS, and ISO certifications.

Reputed wire manufacturers provide:

-

Quality-tested materials

-

Consistent copper purity

-

Advanced manufacturing processes

-

Environmental compliance

-

Technical support

Partnering with experienced manufacturers ensures long-term reliability and reduced operational risks.

How to Choose the Right Cable and Wire

When selecting electrical wiring products, consider the following factors:

1. Application Requirements

Identify voltage levels, current capacity, and environmental conditions.

2. Copper Quality

Look for high-conductivity, oxygen-free copper for better performance.

3. Insulation Type

Choose PVC, XLPE, or enamel coating based on usage.

4. Wire Gauge

Select the appropriate copper wire gauge to prevent overheating.

5. Certification

Ensure compliance with national and international standards.

6. Manufacturer Reputation

Work with trusted wire manufacturers for consistent quality.

Sustainability and Energy Efficiency in Wiring

Modern electrical systems prioritize energy efficiency and environmental responsibility. High-quality copper wiring reduces energy loss and carbon footprint over time.

Many wire manufacturers now focus on:

-

Eco-friendly insulation materials

-

Recycling programs

-

Energy-efficient production

-

Reduced waste processes

These initiatives contribute to sustainable infrastructure development.

Future Trends in Power Cables and Wiring

The electrical industry continues to evolve with smart grids, renewable energy, and automation. Future wiring solutions will focus on:

-

Smart monitoring cables

-

High-temperature insulation

-

Fire-resistant materials

-

Lightweight conductors

-

Digital fault detection

As demand grows, innovations in electrical power cable and copper wire technology will play a vital role in supporting smart cities and digital transformation.

Conclusion

From residential buildings to large industrial facilities, high-quality wiring forms the foundation of reliable electrical systems. Choosing the right electrical power cable, understanding copper wire gauge, and using trusted wire manufacturers ensures safety, efficiency, and long-term performance.

Products such as PVC copper wire, PVC wire, enamelled copper wire, copper strip, stranded wire, and industrial power cable solutions serve diverse applications across multiple sectors.

By investing in certified materials and working with experienced suppliers, businesses and individuals can build electrical systems that are safe, sustainable, and future-ready.